隨著鋰(li)離(li)子電(dian)(dian)(dian)池(chi)(chi)在(zai)手機、電(dian)(dian)(dian)腦、汽車、儲能等領域(yu)的(de)(de)(de)廣(guang)泛(fan)應(ying)用,人(ren)們對電(dian)(dian)(dian)池(chi)(chi)的(de)(de)(de)安(an)全性(xing)、能量密(mi)(mi)度(du)和(he)功率(lv)密(mi)(mi)度(du)性(xing)能的(de)(de)(de)需求越來越高(gao)。為了(le)提高(gao)鋰(li)離(li)子電(dian)(dian)(dian)池(chi)(chi)的(de)(de)(de)能量密(mi)(mi)度(du)和(he)功率(lv)密(mi)(mi)度(du),一些鋰(li)電(dian)(dian)(dian)新材料(liao)(liao)和(he)新技(ji)術亟待開發。鋰(li)離(li)子電(dian)(dian)(dian)池(chi)(chi)生(sheng)產由多(duo)個工(gong)(gong)藝過(guo)程組成,為了(le)得(de)到安(an)全可(ke)靠(kao)性(xing)高(gao)且性(xing)能一致性(xing)好的(de)(de)(de)電(dian)(dian)(dian)池(chi)(chi),需要(yao)對每一個生(sheng)產工(gong)(gong)藝制定嚴格的(de)(de)(de)監控(kong)(kong)措施,確保不良(liang)品不流入市場。為了(le)節約生(sheng)產成本,提升(sheng)生(sheng)產效率(lv),電(dian)(dian)(dian)池(chi)(chi)企業更加希望能在(zai)前工(gong)(gong)序(xu)階(jie)段就能快速識別出(chu)(chu)異常,及時做出(chu)(chu)相應(ying)改善措施。目前大多(duo)數電(dian)(dian)(dian)池(chi)(chi)企業在(zai)前工(gong)(gong)序(xu)常用的(de)(de)(de)監控(kong)(kong)方法(fa)主要(yao)包(bao)括監控(kong)(kong)以(yi)下參(can)數:漿料(liao)(liao)黏(nian)度(du)、漿料(liao)(liao)固含量、涂布質量、壓實密(mi)(mi)度(du),這些方法(fa)雖(sui)然可(ke)以(yi)一定程度(du)上監控(kong)(kong)出(chu)(chu)工(gong)(gong)序(xu)波動,但還(huan)不足(zu)以(yi)滿足(zu)監控(kong)(kong)成品電(dian)(dian)(dian)芯一致性(xing)的(de)(de)(de)要(yao)求。極(ji)(ji)片(pian)是電(dian)(dian)(dian)池前端工(gong)(gong)序的(de)(de)一個重要輸出,極(ji)(ji)片(pian)的(de)(de)電(dian)(dian)(dian)子電(dian)(dian)(dian)阻(電(dian)(dian)(dian)導率(lv))影響全電(dian)(dian)(dian)池的(de)(de)功率(lv)性(xing)(xing)、可(ke)靠性(xing)(xing)及(ji)安全性(xing)(xing),同(tong)時它又與攪(jiao)拌(ban)、涂布和(he)輥壓工(gong)(gong)序息息相關,因此,測量極(ji)(ji)片(pian)電(dian)(dian)(dian)阻的(de)(de)變化(hua)可(ke)以(yi)較好地評(ping)價極(ji)(ji)片(pian)制(zhi)(zhi)作過程中電(dian)(dian)(dian)子導電(dian)(dian)(dian)網絡的(de)(de)性(xing)(xing)能(neng),評(ping)估電(dian)(dian)(dian)極(ji)(ji)微觀(guan)結構(gou)的(de)(de)均(jun)勻性(xing)(xing)以(yi)及(ji)監(jian)控極(ji)(ji)片(pian)制(zhi)(zhi)作工(gong)(gong)藝的(de)(de)穩定性(xing)(xing),助力改進極(ji)(ji)片(pian)的(de)(de)配方以(yi)及(ji)攪(jiao)拌(ban)、涂布和(he)輥壓工(gong)(gong)藝的(de)(de)控制(zhi)(zhi)參數(shu)。

目前,測試極片電子電阻主要有兩種原理:四探針法和兩探針法。四探針法只能表征極片表面涂層的電阻,忽略了涂層和集流體的界面電阻,與極片在電池中的實際使用情況不符,因此不用于測試鋰離子電池極片電阻1-2。兩探針法能表征極片的整體穿透內阻,包含涂層電阻、涂層與集流體界面電阻以及集流體本身電阻,測試時的電子傳導路徑與極片在電池中實際使用時的電子傳導路徑相同,大多數企業和科研工作者采用該方法進行極片電阻表征2-4。本文(wen)使用的(de)方法是在兩(liang)探針法的(de)基礎(chu)上做進一步改進,采用四線法加可(ke)控(kong)(kong)壓(ya)雙圓盤電(dian)極(ji),測試極(ji)片(pian)電(dian)子(zi)電(dian)阻,監控(kong)(kong)涂布和輥壓(ya)工(gong)序極(ji)片(pian)電(dian)阻的(de)變化,將電(dian)芯的(de)風(feng)險控(kong)(kong)制(zhi)提前(qian)至極(ji)片(pian)端,從而為鋰(li)離(li)子(zi)電(dian)池研發和生產保駕護航。

1.工藝監控案例(li)

1.1 極片批次穩定性監(jian)控

極片電阻受導電劑分散、涂布重量、冷壓參數等多種因素影響,其中導電劑對電阻的影響非常顯著3。正極導電劑的分散情況與漿料配方、攪拌條件、涂布/烘干條件等眾多復雜工藝控制參數有關,導電劑分散不均將極大惡化電池動力學性能,但不均勻性很難通過極片外觀、粘接力等常規監控手段發現,往往容易被忽略,造成不可挽回的損失。

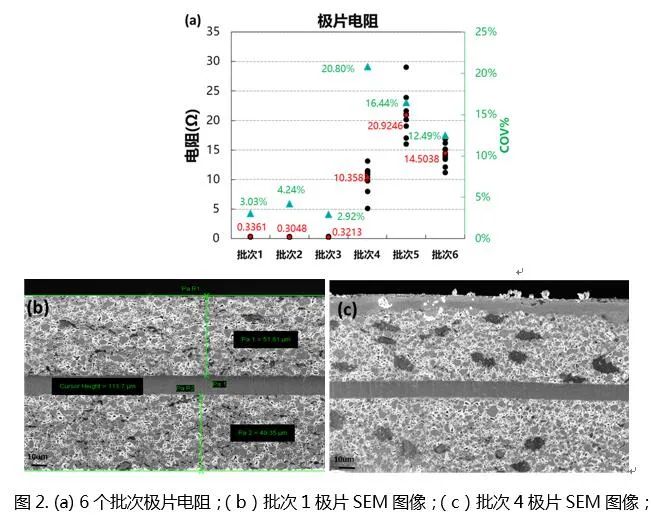

在電(dian)(dian)(dian)芯研發初(chu)(chu)期,通過對三元極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)的(de)(de)(de)大(da)量測(ce)(ce)試和(he)監(jian)控(kong),初(chu)(chu)步(bu)制(zhi)定正(zheng)常(chang)(chang)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)范圍為(wei)0.2~0.4Ω,在電(dian)(dian)(dian)芯導(dao)(dao)入量產階段(duan)后,對不同批(pi)次(ci)(ci)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)進行(xing)(xing)(xing)電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)監(jian)控(kong)。如圖(tu)2(a)是(shi)(shi)對6個批(pi)次(ci)(ci)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)進行(xing)(xing)(xing)的(de)(de)(de)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)測(ce)(ce)試,黑色數據(ju)點代(dai)表單次(ci)(ci)測(ce)(ce)試電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)值(zhi),紅色數據(ju)點代(dai)表電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)均(jun)值(zhi),綠色數據(ju)點代(dai)表電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)COV。從電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)數據(ju)可發現有3個批(pi)次(ci)(ci)電(dian)(dian)(dian)芯極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)大(da)于0.4Ω,明(ming)顯(xian)超出規格,進一步(bu)對正(zheng)常(chang)(chang)和(he)異常(chang)(chang)批(pi)次(ci)(ci)的(de)(de)(de)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)進行(xing)(xing)(xing)SEM形貌(mao)分(fen)析,如圖(tu)2(b)和(he)2(c),正(zheng)常(chang)(chang)批(pi)次(ci)(ci)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)中導(dao)(dao)電(dian)(dian)(dian)碳的(de)(de)(de)分(fen)布較均(jun)勻,而異常(chang)(chang)批(pi)次(ci)(ci)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)的(de)(de)(de)導(dao)(dao)電(dian)(dian)(dian)碳出現明(ming)顯(xian)的(de)(de)(de)團聚現象(xiang),由于測(ce)(ce)試極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)時是(shi)(shi)隨機選取極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)不同位置,導(dao)(dao)電(dian)(dian)(dian)碳分(fen)布不均(jun)會(hui)導(dao)(dao)致無導(dao)(dao)電(dian)(dian)(dian)碳的(de)(de)(de)位置處極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)明(ming)顯(xian)增大(da)。因此,通過監(jian)控(kong)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)電(dian)(dian)(dian)阻(zu)(zu)(zu)(zu)(zu)的(de)(de)(de)變化可在極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)端快速識(shi)別(bie)異常(chang)(chang)極(ji)(ji)(ji)片(pian)(pian)(pian)(pian),避免不良極(ji)(ji)(ji)片(pian)(pian)(pian)(pian)流入下一工序,節(jie)約(yue)生產成本。

1.2 極片涂布均(jun)勻性(xing)監控

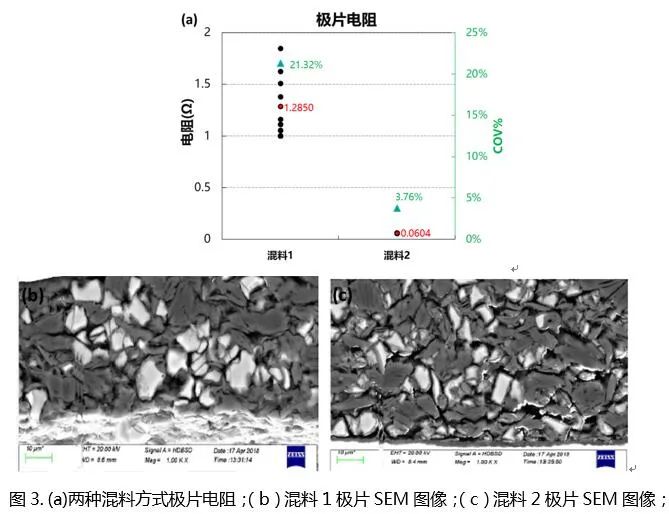

為了提升電池能量密度,硅碳混(hun)合材(cai)(cai)料作為鋰(li)離子電池負極(ji)材(cai)(cai)料的(de)研究逐漸增多(duo),如何(he)控制硅碳混(hun)合材(cai)(cai)料在極(ji)片中的(de)分布均勻性對負極(ji)的(de)膨脹以及(ji)電位分布有(you)顯著(zhu)影響(xiang)。監控不同工藝參數條(tiao)件下極(ji)片電阻的(de)變(bian)化可評估硅碳材(cai)(cai)料混(hun)合均勻性。

如(ru)圖(tu)3是兩種混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)工藝的(de)(de)極(ji)片(pian)(pian)(pian)進(jin)行的(de)(de)極(ji)片(pian)(pian)(pian)電阻(zu)測試和(he)SEM形(xing)貌表征結果。由圖(tu)3(a)可(ke)看出混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)1的(de)(de)極(ji)片(pian)(pian)(pian)電阻(zu)均(jun)值(zhi)和(he)COV均(jun)明(ming)顯高于混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)2組,說明(ming)混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)1的(de)(de)均(jun)勻性差(cha)于混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)2 的(de)(de)極(ji)片(pian)(pian)(pian)。結合圖(tu)3(b)和(he)3(c)SEM形(xing)貌分析可(ke)看出,混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)1組極(ji)片(pian)(pian)(pian)中(zhong)硅(gui)(gui)碳的(de)(de)混(hun)(hun)合不(bu)均(jun)勻,有較(jiao)多單獨的(de)(de)硅(gui)(gui)顆粒(li)存(cun)在,因此導致極(ji)片(pian)(pian)(pian)電阻(zu)均(jun)值(zhi)增大,且不(bu)同位置處(chu)的(de)(de)極(ji)片(pian)(pian)(pian)電阻(zu)差(cha)異(yi)較(jiao)大,從而電阻(zu)COV較(jiao)大,而混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)2組中(zhong)硅(gui)(gui)碳混(hun)(hun)合相(xiang)對(dui)均(jun)勻,電阻(zu)的(de)(de)均(jun)值(zhi)和(he)COV均(jun)較(jiao)小,進(jin)一步證明(ming)混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)2對(dui)應的(de)(de)混(hun)(hun)料(liao)(liao)(liao)(liao)(liao)工藝較(jiao)好。

2.總結(jie)

本文使(shi)用的四線法加(jia)可控壓雙圓盤電極(ji)的方法測試極(ji)片電阻,能較好的應用于監控極(ji)片工(gong)藝(yi)的穩定性和均勻(yun)性,且(qie)極(ji)片電阻數(shu)據(ju)(ju)可實時連接BIS或MES系統,實現數(shu)據(ju)(ju)的可記錄、可追溯。目前已有(you)多家材料和電池企業將該(gai)方法導入產線工(gong)藝(yi)監控,對(dui)工(gong)藝(yi)參數(shu)及工(gong)藝(yi)穩定性進(jin)(jin)行快速有(you)效的評(ping)估,將電芯的風險(xian)控制提前至極(ji)片端,加(jia)速鋰(li)離子(zi)電池研發和生產進(jin)(jin)度(du),滿足市(shi)場需(xu)求。